Still, like many things in life, project management is a matter of chipping away at things. A bit at a time. So lately I've been playing around with the seat when I have a few minutes.

The first thing that became obvious was, it was bent...

I've realized that this is a common problem on seats of this era. Get a heavy driver and the door side part of the seat back bends backwards warping the whole frame. In my case, it had bent back so far that the lower tube in the seat back had broken off at the weld. I think this car had also been in an accident, so that wouldn't help.

The first thing I did was bend back the tabs and throw the old back springs in the bin. I wasn't using them again. Although I have to say, they were well attached. The lower tube was pretty rusty though, so I just cut it off. It was already fatigued, why keep it?

I had a few goes at straightening things. The first go included a butane torch, but not much success. In fact the only thing I did successfully was burn one of my knees quite badly when I brushed the hot metal.

I gave up on the torch and spent a while trying to figure out where it was warped. Again, had no success with that. A friend of mine said, "maybe it's just twisted in the corners". She was right. Literally 30 seconds in the vice and a bit of a twist got it straight again.

With that all done, I was left with all the tabs and hooks that hold the springs and upholstery on to the seat. I'm not going to be using them and I knew they get in the way, so I drilled out the spot welds and knocked them all off with a drift and a lump hammer.

This took an hour or so and the welds on the back had much better penetration than on the base, so there's still a little cleaning up of things to do. But basically, I'm left with this...

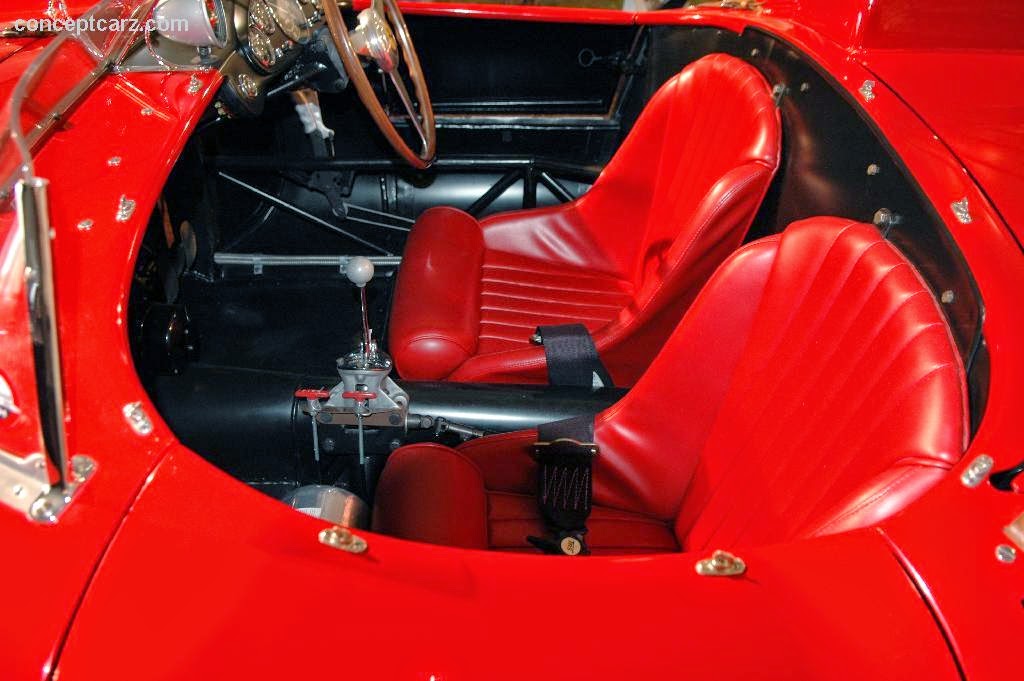

So this is where it all begins in a way. Now, how to get from my nasty old seat base to this style of seat from a 56' Ferrari?

The temptation is to over-engineering things. By that I mean create something is better than factory, better than period, and better than a million bomber seats I see on the interwebs. So I need a few criteria to begin with. To get them I should ask this question...

It's the late 1950s, what would a club racer build in his backyard?

Or better still...

What COULD a club racer build in his backyard?

This rules out a bunch of things; no CNC, no Complex sheet metal, no shiny powdercoating... If I wanted to be strict, I'd get rid of the MIG welder and braze it together, but I think I can get over myself there. So I think it's something like this...

1. As few welds as possible.

2. As little extra metal as possible.

3. Keeping the majority of the factory frame and fittings.

4. Strategic bracing.

5. Plywood backing for the back and schwab.

6. Maybe some speed holes, but nothing ostentatious.

7. Most of the structure hidden under the covering.

So, with all that in mind, let the games begin!

No comments:

Post a Comment